Epoxy on Steroids: Polyurea/Polyaspartic (Deal only in Dallas Fort Worth)

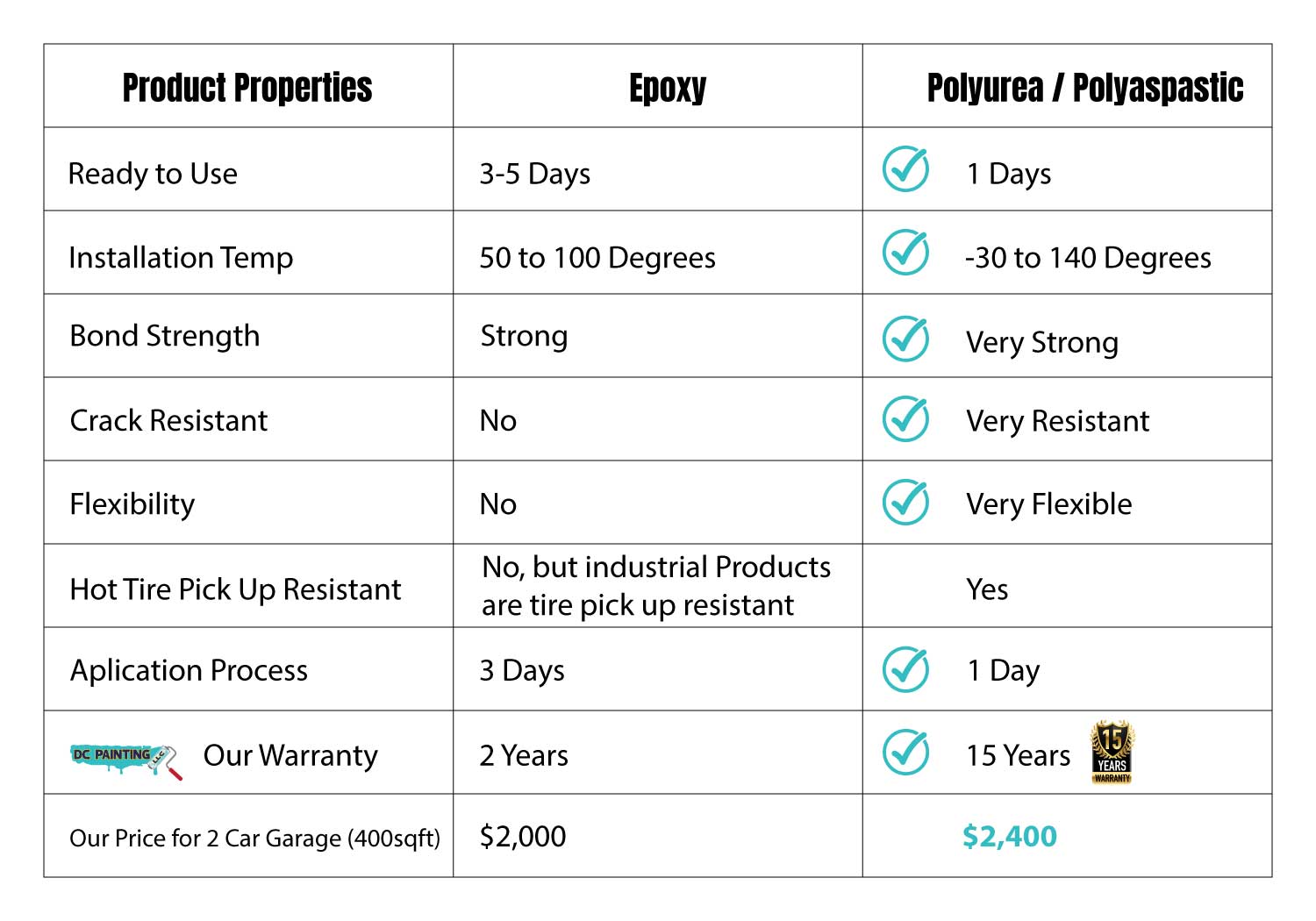

Price range: $2,400.00 through $2,800.00

1-DAY SYSTEM

Detail 1 Day Process

Step 1: Moisture Testing & Site Inspection

We begin by performing a Moisture Vapor Transmission Test to ensure the surface is within acceptable

limits for coating application. Current moisture reading: ___.

We also assess the overall floor condition and surrounding environment to ensure safe and optimal application. It is essential that a moisture reading is documented prior to proceeding.

Step 2: Surface Preparation

The concrete surface is diamond ground to open the pores and allow for deep penetration and superior bonding of the coating system. All adjacent areas not being coated are carefully masked or covered for protection. This step ensures a clean and properly profiled surface, essential for long-term adhesion. Does not include previously coated concrete. If existing epoxy coatings need to be removed, it will add approximately $1/sqft to the cost.

Step 3: Crack & Surface Repairs

We fill visible cracks and small holes using a high-performance concrete repair compound—up to 1 quart included at no additional charge.

Additional material, if needed, is available at $60 per quart.

After repairs have cured, we sand and smooth the areas to promote proper adhesion. The floor is then thoroughly cleaned by sweeping, vacuuming, or mopping to remove dust and debris.

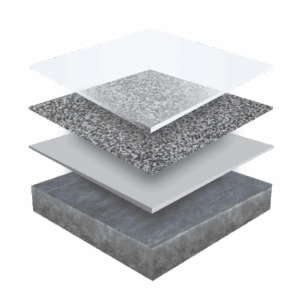

Step 4: Polyurea Base Coat Application

A high-grade polyurea base coat is applied using a squeegee and roller technique for uniform coverage. Polyurea provides enhanced durability and flexibility compared to traditional epoxy coatings, making it ideal for high-traffic and high-impact environments.

Step 5: Decorative Flake Broadcast

While the base coat is still wet, we apply a full-broadcast decorative flake system. This provides texture, color, and slip resistance.

Once cured, excess flakes are scraped and vacuumed to achieve a clean, level surface before sealing.

Step 6: Polyaspartic Top Coat

We finish with an industrial-grade polyaspartic top coat that delivers a sleek finish and maximum protection. This fast-curing coat allows light foot traffic within 24 hours.

For enhanced durability, a second top coat can be added at $0.75 per sq. ft..

All work areas will be cleaned, and debris will be removed from the site upon completion.

Step 7: Final Walkthrough & 15-Year Warranty

Once completed, your floor will be ready for normal use in 24 hours.

For full details, including terms and warranty information, please click here.

*Restrictions may apply.

Additional information

| Size | 2 Car Garage up to 400sqft, 3 Car Garage up to 650sqft |

|---|

Polyurea belongs to the broader family of polyurethane materials. Similar to epoxy systems, polyurea consists of two components—a resin and a curing agent—that combine to initiate a hardening process. Boasting a composition of approximately 98% solids, polyurea is about four times stronger than epoxy and offers nearly double the flexibility. Its high elasticity (around 300%) allows it to handle the natural expansion, contraction, and movement of concrete surfaces without forming cracks.

This material has a proven track record of durability, with over 25 years of performance in real-world applications

Training

Want to learn how to apply, we can do group or individual training.

Purchase Product

We can help you buy in bulk or small size at our discounted rate. National and Local distributor.

Grinding Service

Do you have a project? if you don’t have the equipment, why rent for $400-$500/day? We can give you a free estimate.